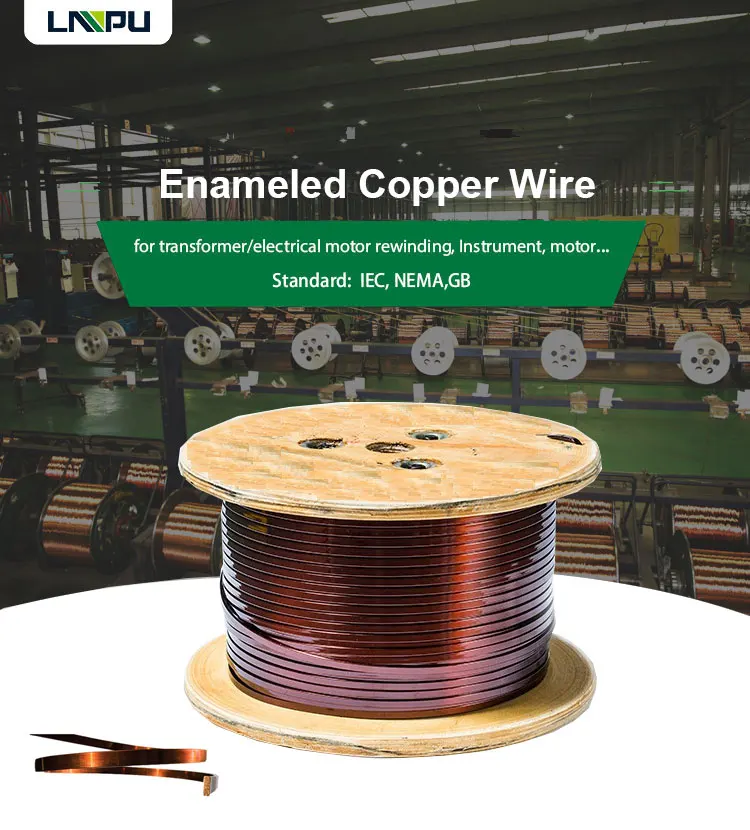

Overview

Enameled Copper Wire is made of copper rod, which are draw by the specification mould,it is the baked winding wire with multiple-layers of insulating paint after annealing softening treatment.

Essential details

| Place of Origin: |

Henan, China |

Brand Name |

LP |

| Model Number: |

Enameled Wire |

Insulation Type |

Single,Heavy,Triple |

| Application: |

Polyvinyl Formal Enameled Wire PVF Wire for Oil-filled transformers, Armature winding, Motors, etc |

Conductor Material: |

Copper |

| Conductor Type: |

Solid |

Insulation Material: |

Enameled |

| Product name: |

Polyvinyl Enameled Copper Flat Wire |

Standard: |

IEC NEMA GB JIS |

| Certification: |

SGS,UL,ISO9001,ISO4001 |

Temperature Class: |

105℃ 120℃ |

| Diameter(mm): |

round:0.4-2.5,flat:15-40mm2 |

MOQ: |

300kg |

| Bobbin: |

PT-30, PT-60, PT-90, PT-200, 50KG 150KG |

Other name: |

Polyvinyl-Formal Enameled Round (Rectangular) Copper or Aluminum Wire |

Supply Ability

Supply Ability: 1500 Kilogram/Kilograms per Week

Packaging & delivery

Packaging Details:

Supplier PVF Polyvinyl Acetal Enameled Copper Flat Wire Packaging Details:PT-30, PT-60, PT-90, PT-200, 50KG 150KG,Plastic Spool, Wooden Spool, Wooden Cases, or according to customer's requirements

Port:

Qingdao,Shanghai,Tianjin,HK

Lead time:

| Quantity(kilograms) |

1 - 500 |

>500 |

| Lead time (days) |

5 |

To be negotiated |

Product Description

Details Tech Information:

| Product Name |

Flat Copper Magnet Wire |

| Conductor |

Copper |

| Dimension |

Diameter: a:0.8 ~ 8mm;b:2.0-22mm |

| Thermal Class (℃) |

120(Class E);180 (Class H);200 (Class C);220 (Class C+); 240(Class HC) |

| Insulation thickness |

G1;G2;G3;G4 |

| Certificate |

UL |

| Standard |

IEC,NEMA,GB,JIS |

| Packing |

30kg-150kg ply-wood spool(250*400/250*500/250*600/250*730) |

| Appication |

Transformer; motor;generator; modern instrument; welding machine and so on |

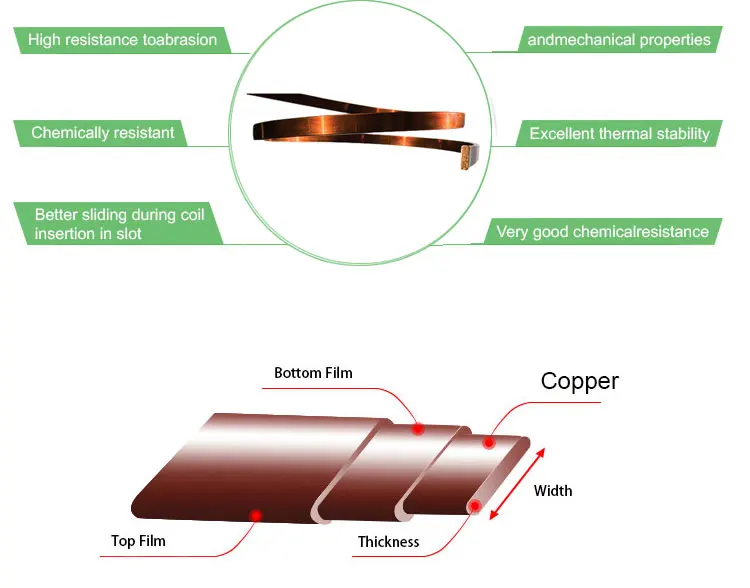

Modern Enamelled Aluminium Magnet Wire or Enameled Copper Magnet Wire typically uses one to three layers of polymer film insulation, often of two different compositions, to provide a tough, continuous insulating layer. Magnet wire insulating films use (in order of increasing temperature range) polyvinyl formal or Formvar (PVF), polyurethane, polyamide (PUW), polyester (PEW), polyester-polyimide (EIW), polyamide-polyimide (or amide-imide) (AI-EIW), and polyimide (AIW). Polyimide insulated magnet wire is capable of operation at up to 250°C. The insulation of thicker square or enamelled rectangular aluminium or copper magnet wire is often augmented by wrapping it with a high-temperature polyimide or fiberglass tape, and completed windings are often vacuum impregnated with an insulating varnish to improve insulation strength and long-term reliability of the winding.

There are myriad electrical applications that rely on enameled rectangular wire. Because of its ability to reduce corona discharge, enamel rectangular wire increases safety and reduces costly electric energy wastage. These wires are also fire-resistant, making them a safe choice to use with equipment that may be exposed to intense heat or flames. It is also easy to wind and store.

Application

Certifications